"Urambo Tauro" (urambotauro)

"Urambo Tauro" (urambotauro)

09/21/2016 at 12:00 ē Filed to: cl100, honda, motorcycle, project, wrenching, blog

1

1

11

11

"Urambo Tauro" (urambotauro)

"Urambo Tauro" (urambotauro)

09/21/2016 at 12:00 ē Filed to: cl100, honda, motorcycle, project, wrenching, blog |  1 1

|  11 11 |

Now that the carburetor is rebuilt, itís on to the engine.

One of the first things I did when I started working on this bike was drain the oil, which revealed some interesting metal particles that had settled to the bottom. Iíve been straining the old oil through a paper towel, and rinsed off the pieces with carb cleaner to have a better look at them.

Pic before cleaning the oil off.

There are some tiny chunks, bigger than a grain of sand, that had been caught by the screen. There are also a few rounded slivers that clearly used to be drain plug threads (see pic at bottom of post). According to my father, he never had any problems with the bike, and that it indeed ďran when parkedĒ. But the drain plug was something that he did have trouble with, and I was about to find out why.

The plug had been replaced with what was clearly a 1/2"-13 bolt, cut down to size. But that bolt wasnít sealing very well, despite his best attempts, which included two cork washers, one (nylon?) washer, and a smear of RTV. Threading the plug back in revealed why sealing had been so difficult:

The bolt was cockeyed about 10į, pinching the washers on one side, but not the other. I attempted a re-tap, preparing myself to have to go get a bigger plug if necessary.

It became necessary.

The plug seemed to thread into its new threads nicely, but I wasnít feeling good about cross-threading the existing threads, and the narrow head of the bolt wasnít providing much of a sealing surface anyway. It wouldnít hold oil, not even with this O-ring I happened to have on-hand. It was time for a proper plug with a proper washer.

I picked up a M14-1.5 drain plug and gently laid the bike on its side. I then re-drilled and re-tapped the hole as straight as I could to accommodate the new drain plug, greasing the tap to collect cuttings, and pouring a little oil in with the bike upright to ďrinseĒ remaining particles out.

The new plug seemed to snug up nicely with its included washer, but I avoided putting much torque on it. All of my cars have had steel oil pans, and aluminum makes me nervous. Without any specs available, I took out my torque wrench and stopped tightening after 12 lb-ft, which felt tight enough, I guess.

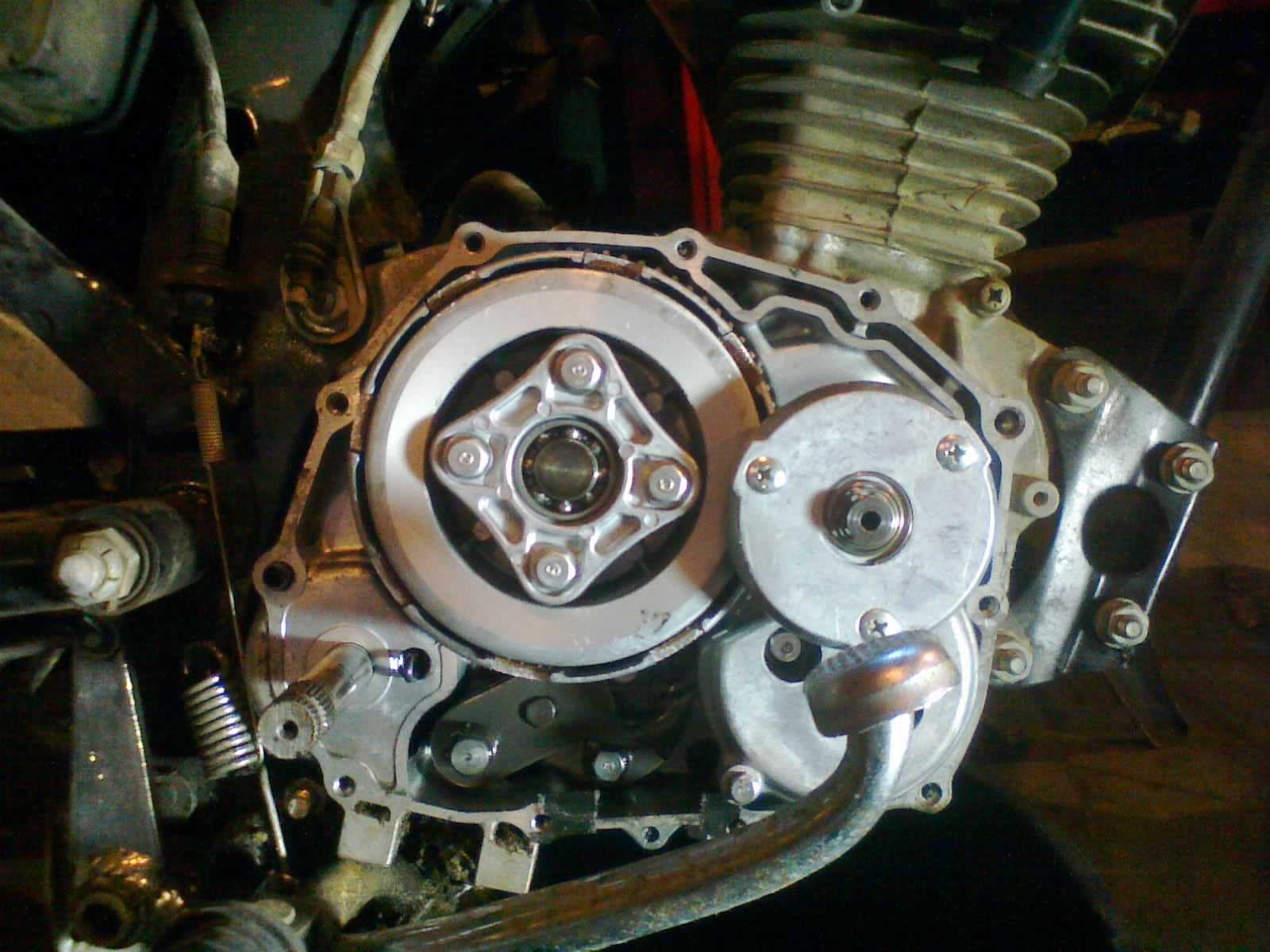

As part of the oil change, this bike introduced me to a new type of oil filter. Itís called a ďcentrifugalĒ oil filter, which was hiding behind the clutch cover. Thatís right: each oil change involves removing the kick-start lever (1 bolt), the step bar (4 bolts), and the side cover (11 screws) to open up the engine. And to make things even more interesting, Honda decided to use Philips-head screws for that engine cover.

WAIT. Those arenít those JIS screws Iíve heard about are they? No? Good. I donít have any of those screwdrivers. Moving on...

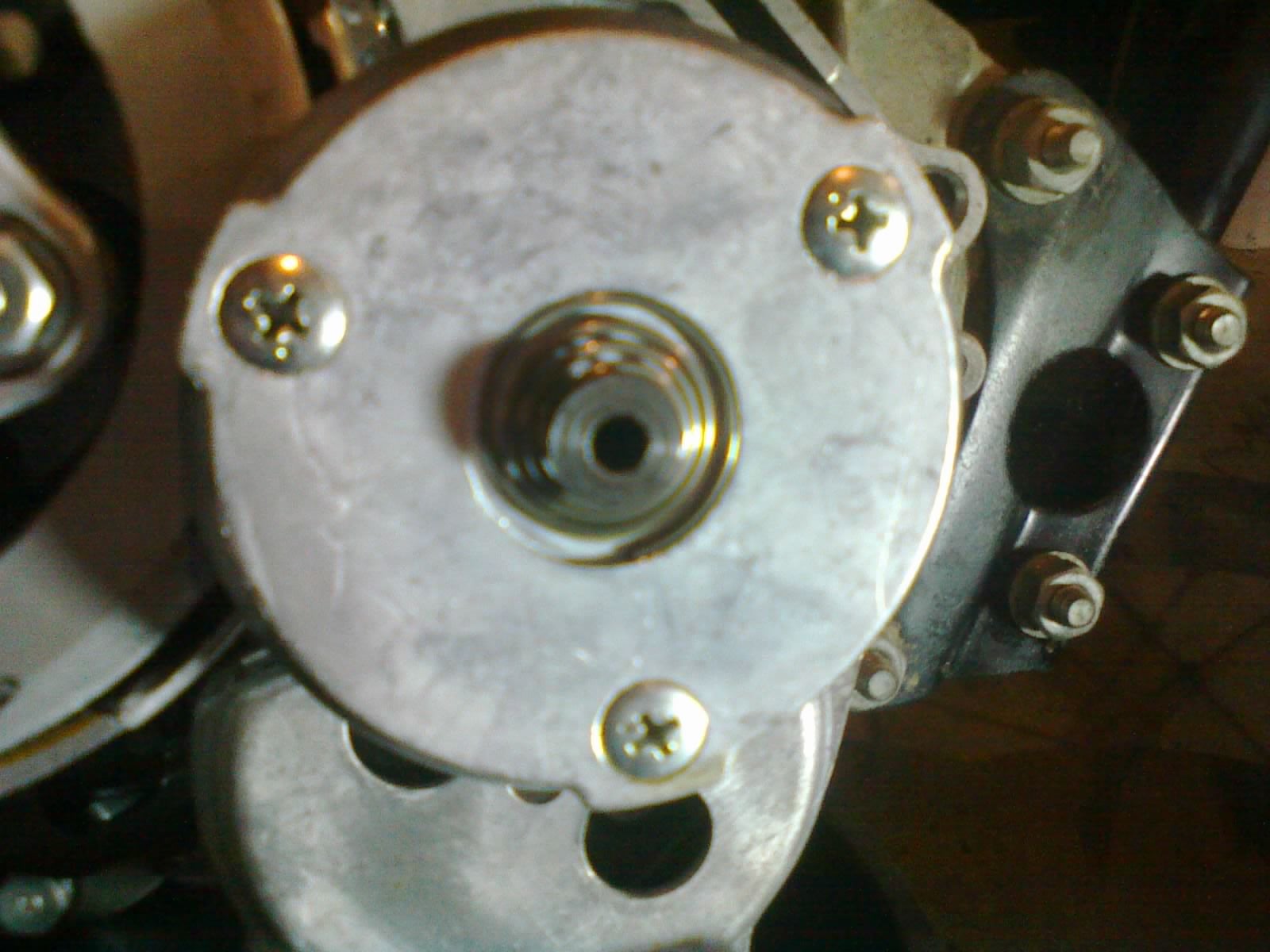

With the cover off, the next step is to remove the cap on the right, held in by three screws. I tried to loosen the first screw, only to feel my screwdriver start to slip. *looks closer*

DAMN IT. Those are JIS screws, as indicated by the little dot. DAMMIT DAMMIT DAMMIT. Or maybe I should say oh cock ...

Ever since learning about JIS screws on James Mayís !!!error: Indecipherable SUB-paragraph formatting!!! Iíd been casually hunting for JIS screwdrivers during trips to tool stores. No dice. Iíd have to order them.

Which would take another few days.

Before placing an order, Iím gonna try something...

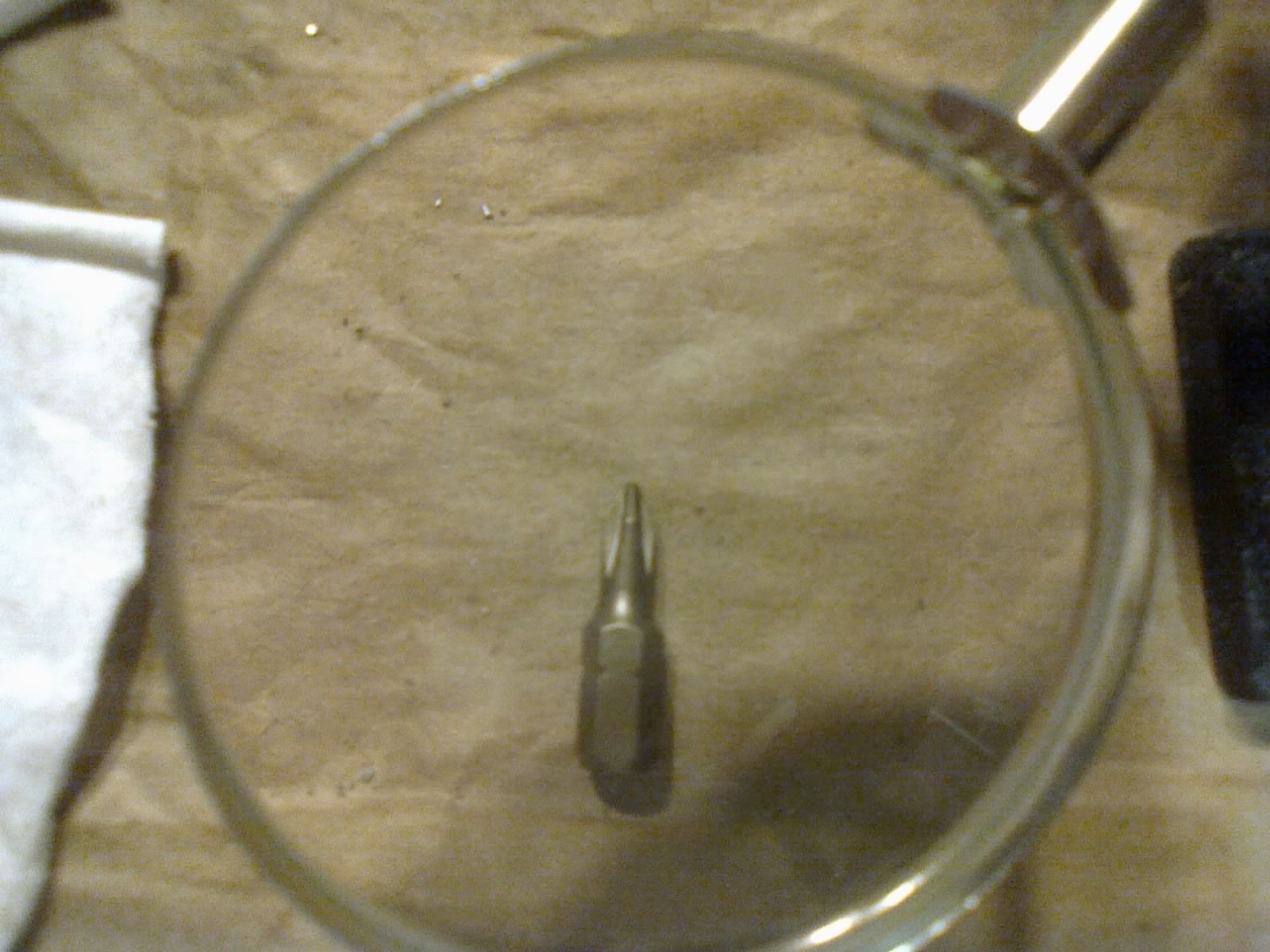

I took a philips bit and cut part of the tip off. I then took a Dremel with a cutoff wheel and VERY CAREFULLY widened the four flutes where the cross-section thickens to join the base of the bit.

MSPaint visualization of my cut lines.

Ta-da! Homemade JIS bit! To my great relief, it worked like a charm. File this one away in the hope you never need bin.

With the cap off, the ďfilterĒ is cleaned by wiping away oil contaminants from the inside of that little cavity. I didnít find any sludge, but I did find a substance like a thin paste, composed of motor oil and aluminum shavings that were even tinier than what the screen had caught. Almost like anti-seize compound, just not as thick.

I wiped it on a towel, next to the rest of the metal that came out of the engine:

I just noticed those large brown chunks near the center of the pic. Not sure how they made it into the picture, but they didnít come out of the engine.

Yuck.

bob and john

> Urambo Tauro

bob and john

> Urambo Tauro

09/21/2016 at 12:05 |

|

All of those shaving are making me mighty nervous I have to admit.

can you take apart the clutch and see what condition the plates are in.

Urambo Tauro

> Urambo Tauro

Urambo Tauro

> Urambo Tauro

09/21/2016 at 12:09 |

|

Those JIS screws are no joke.

Seriously, donít even think about trying to use a regular unmodified philips screwdriver to take them out. These had spent their life in a corrosion-free environment, and were still going to be trouble without the proper tool. I would have ruined the heads had I not stopped at the first sign of trouble.

bob and john

> Urambo Tauro

bob and john

> Urambo Tauro

09/21/2016 at 12:16 |

|

JIS screws are awesome.

princess auto had a FANTASTIC set on sale for $50 when I went looking for them. Love that place.

Tekamul

> Urambo Tauro

Tekamul

> Urambo Tauro

09/21/2016 at 12:28 |

|

It looks like youíre making great progress.

That metal debris doesnít look too bad, it definitely could be from a life of mish-mashed solutions to a missing drain plug.

You went above and beyond with that JIS modification. Iíve gotten by to this point with just the tip ground flat on a #2 philips. But, those are 33 year old screws, so a cautious approach is a good one.

Roadster Man

> Urambo Tauro

Roadster Man

> Urambo Tauro

09/21/2016 at 12:32 |

|

I fuckiní HATE JIS screws. Thatís all I came here to say.

Urambo Tauro

> Tekamul

Urambo Tauro

> Tekamul

09/21/2016 at 12:33 |

|

Iím hoping that the debris is not indicative of a impending failure. The bike doesnít even have 500 miles on it.

The JIS mod was actually my second attempt. I cut up a #2 bit, but once it was ready, I realized that it was too wide to fit inside the screw head. I had to start over with a #1 bit. The shiny metal from the cutting makes it really hard to photograph, but I hope my MSPaint visualization is clear enough to explain the cuts. Iím really pleased with how it came out.

Urambo Tauro

> bob and john

Urambo Tauro

> bob and john

09/21/2016 at 12:33 |

|

It bothers me too. But since the owner hadnít noticed any problems (and heís my father, so I do trust him a little), part of me thinks that it might still be okay.

But hey, Iíve got a couple days before my new clutch cover gasket arrives, so I can totally use that time to have a look at the clutch.

shop-teacher

> Urambo Tauro

shop-teacher

> Urambo Tauro

09/21/2016 at 12:43 |

|

Nice mod to make a JIS bit.

Fingers crossed that all that metal isnít indicative of a failing motor!

Urambo Tauro

> bob and john

Urambo Tauro

> bob and john

09/21/2016 at 12:59 |

|

Princess Auto, huh? Nice tip! I think that I would go ahead and spring for a set if I was going to be encountering JIS screws more often. But this bike is going to going right back to my father, and is just kind of a fun project/learning experience for me, so I think this mod will get me by just fine for now.

If it was MY bike, though, and I had to deal with this on every oil change, Iíd totally jump on getting a real set of JIS screwdrivers.

BTW, does it have to be entire screwdrivers? Does no one make JIS bits?

bob and john

> Urambo Tauro

bob and john

> Urambo Tauro

09/21/2016 at 13:08 |

|

I dont remember seeing just the tips (hehe)

if you are going to be doing any work on Jap bikes, its worth the investment.

IIRC, the brand of the JIS was called ďVesselĒ

Pickup_man

> Urambo Tauro

Pickup_man

> Urambo Tauro

09/21/2016 at 13:45 |

|

My dad has an old wood handle square shaft screw driver that works amazing on any of my Japanese machinery. It would work itís way back and forth between our houses as we ďstoleĒ it from each other. Only very recently did I figure out it was a JIS screw driver. I still have to order a set but at least I donít have to keep stealing Dadís.